Bonds

The properties of a bond influence the grinding characteristics of grinding pins and wheels, i.e. under all circumstances the bond has to hold the diamond or cubic boron nitride grits in a way to resist to the forces and temperatures resulting from the grinding operation until optimal results are achieved. On the other hand the bond has also to leave open space to transport the chips. In order to solve various grinding tasks, a number of different types of bonds is available.

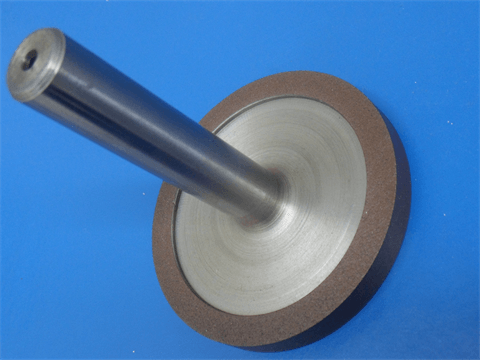

Resin Bonds

Resin Bonds Mounted pins and grinding wheels with resin bonds are used for dry and wet grinding as well as for off hand and automatic grinding as this type of bond can be very well adapted to the grinding parameters. Due to extensive research and development bonds have been found, which due to the characteristics of phenolic and polimid resins, can be used for far more than 50% of all diamond and cubic boron nitride tools.

Metal Bonds

Metal bonds are especially suitable for long-life tools, in general their cutting efficiency (stock removal/time unit) is lower than that of resin bonded tools.

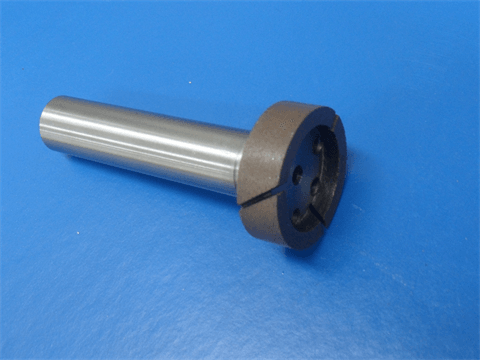

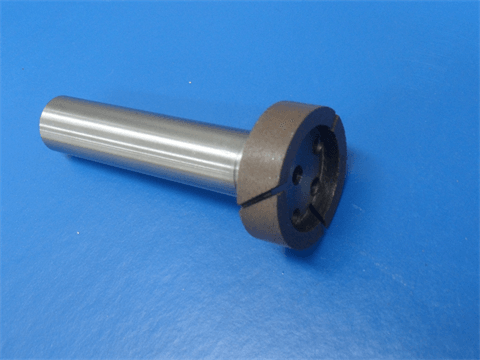

Electroplated Metal Bond

Electroplated Metal Bond FOREVER codes are as follows: -for diamond: S -for CBN: GSS In case of a single layer coating the layer of grit is electroplated to the carrier. Depending on the “thickness” of the galvanic metal bond the grits project from the bond by 30% to 50% of their diameter.. Because of the single layer it is possible to produce galvanic mounted pins of very small diameters. In case of a grit size of D46 or B46 the smallest possible diameter is 0,3 mm.

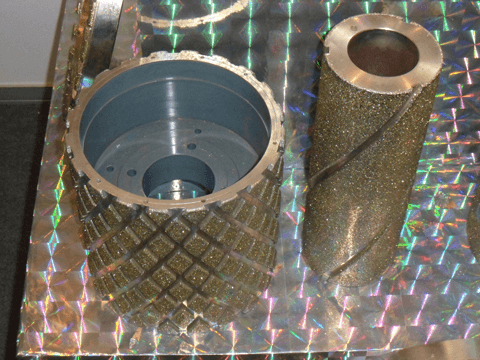

Vitrified bonds

Vitrified diamond and CBN tools have beside others excellent properties regarding their resistance of wear as well as thermal stability. These properties in connection with the wellknown dressability and the adjustable porosity will predestining this bond type for a machining long chipping materials, independing of their grade of hardness.