Application:

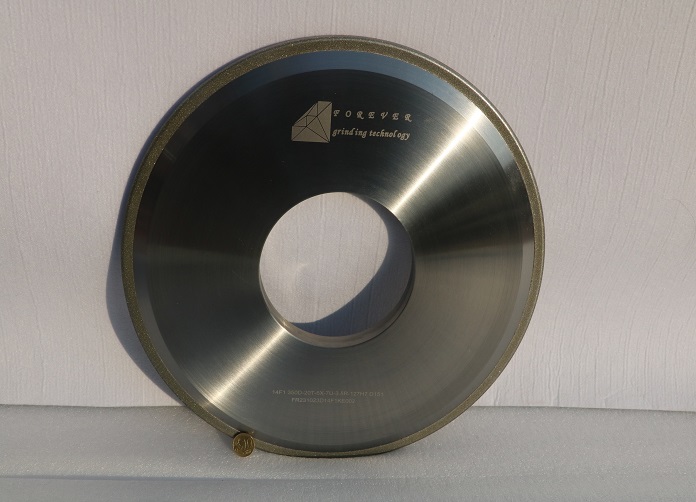

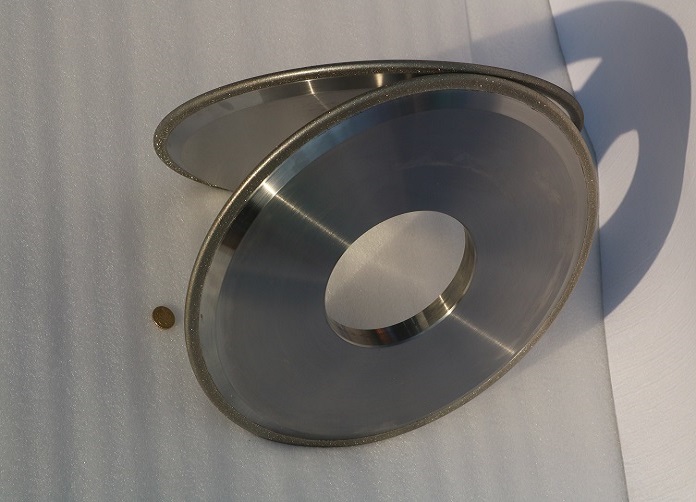

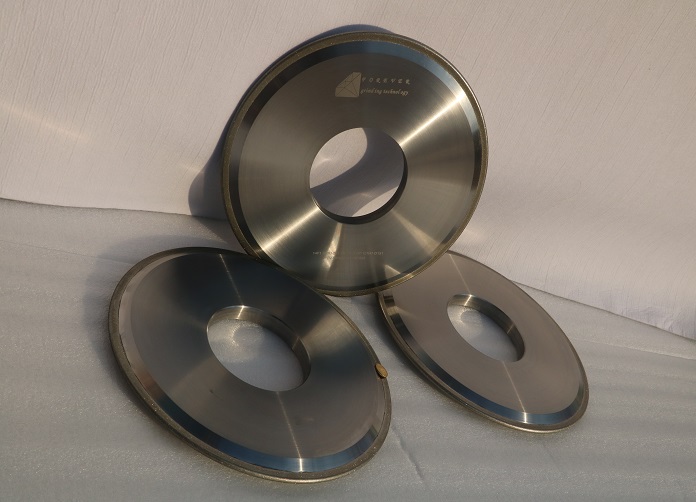

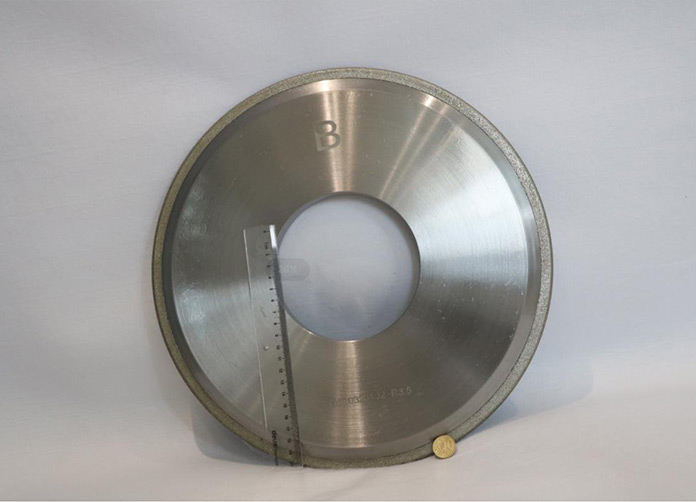

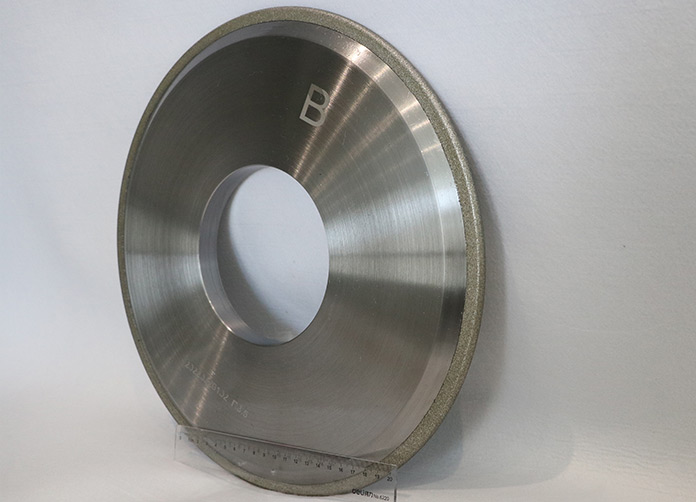

When the grinding wheel works in plunge mode and requires a precision of 0.01 mm for cutting carbide rolls or rings, the wheels used are equally fundamental to obtain an optimal result, since they precisely copy the groove geometries they need to cut or redress. On this condition, for the rigorous geometrical controls, electroplated diamond grinding wheels will be the best choice. Also electroplated diamond grinding wheels do not need dressing and supply best sharpness compared to other.

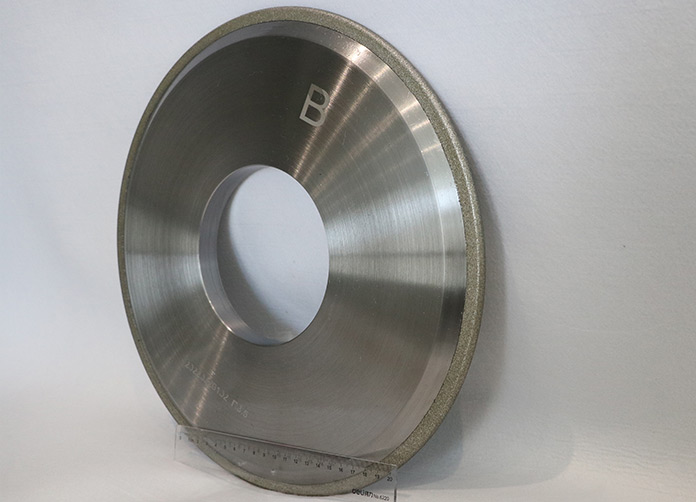

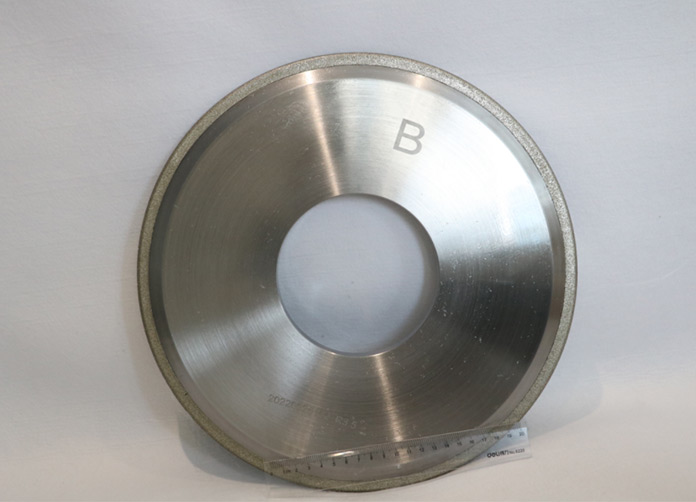

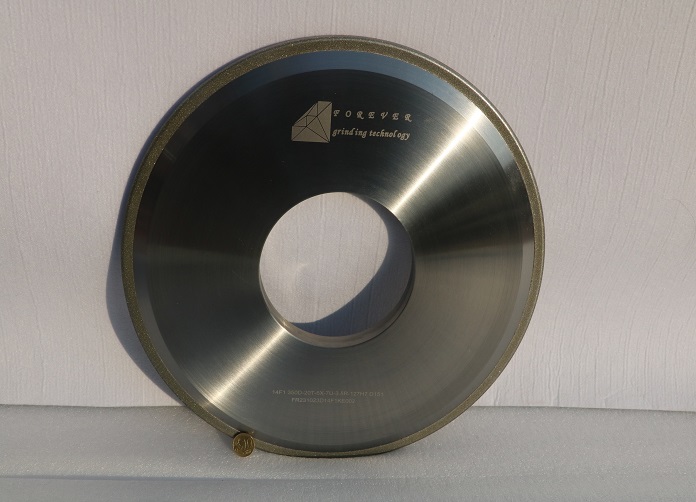

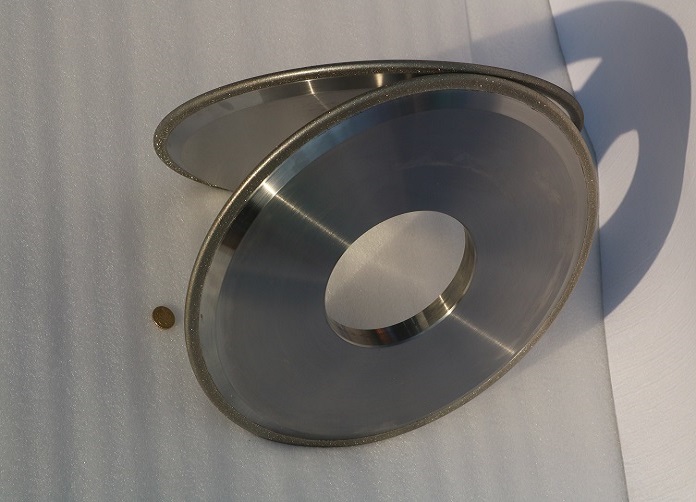

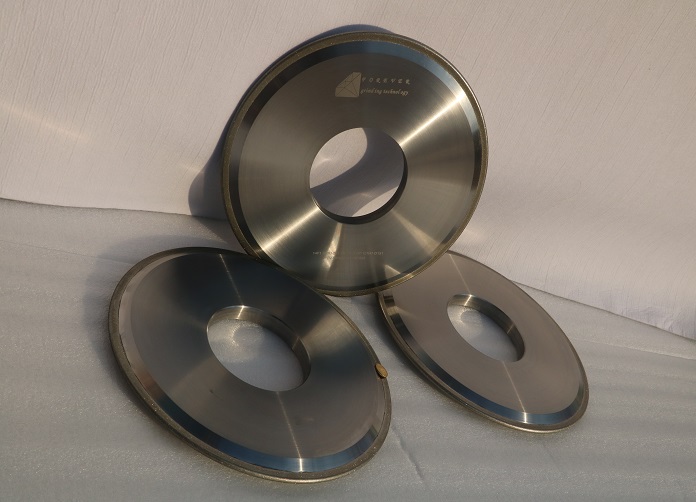

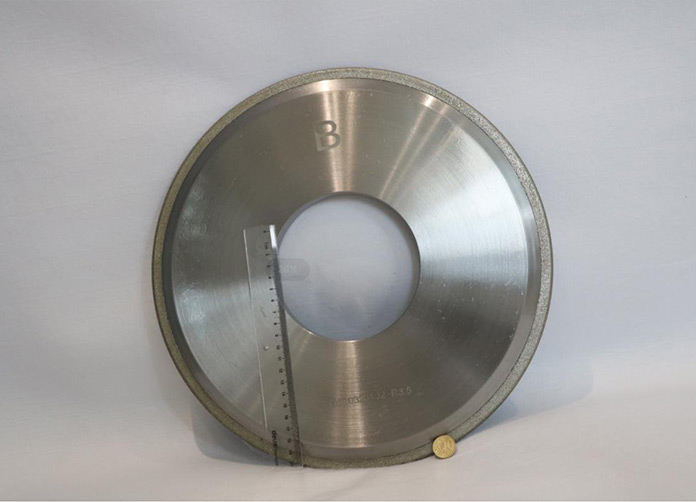

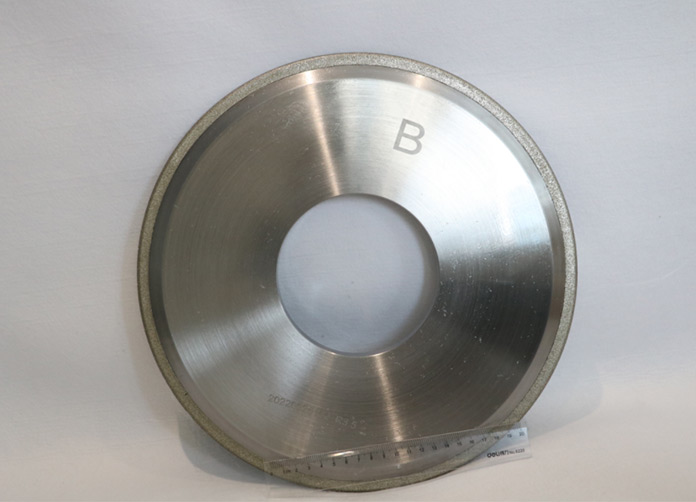

Type: 14F1

MOQ: 2pcs.

Send us email

forever@forever-superabrasives.comCall us

8619937107349When the grinding wheel works in plunge mode and requires a precision of 0.01 mm for cutting carbide rolls or rings, the wheels used are equally fundamental to obtain an optimal result, since they precisely copy the groove geometries they need to cut or redress. On this condition, for the rigorous geometrical controls, electroplated diamond grinding wheels will be the best choice.

Also electroplated diamond grinding wheels do not need dressing and supply best sharpness compared to others bond diamond grinding wheels. So at nowadays stage electroplated diamond grinding wheels are becoming more and more popular in high-end markets of carbide rolls grinding.

We strongly recommend Electroplated Grinding Wheels with Ø 350mm or Ø 250mm.

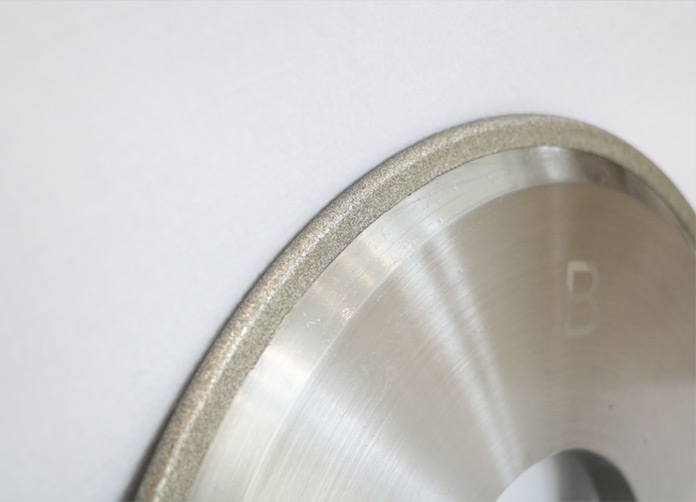

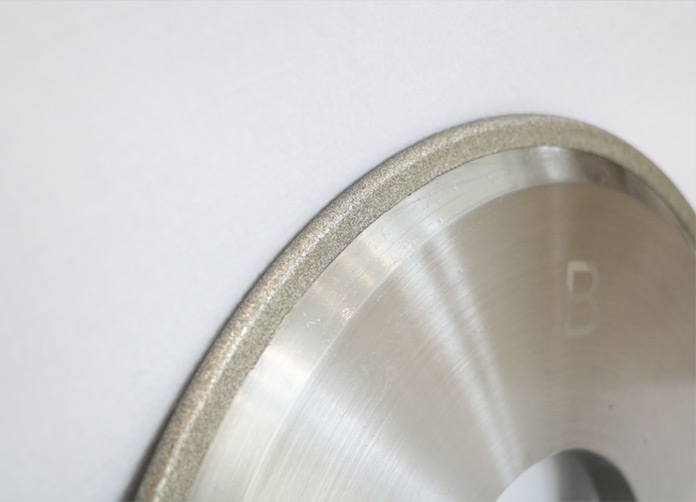

Diamond grains are fixed on the wheel steel body through Nickel galvanic deposited layer. The electro-deposition process is carried out in order to ensure a single crystal diamond layer homogeneously distributed on the working surface and strongly fixed to the wheel body.

Advantages: Compared to traditional metal and resin bond wheels

•No maintenance throughout the whole wheel life: it means saving costs and downtime for wheel changing, checking and redressing

•No need of investment and operational-time for wheel dressing grinder

•Consistency of the results: the electroplated wheels with a good profile retention until they are used up

•Higher removal rate, efficient, lower grinding power due to the excellent sharpness

•Decrease heating of the grinding wheel and work piece

•Cost Efffectiveness: electroplated wheels have lower cost but similar durability compared with metal bond wheels.

|

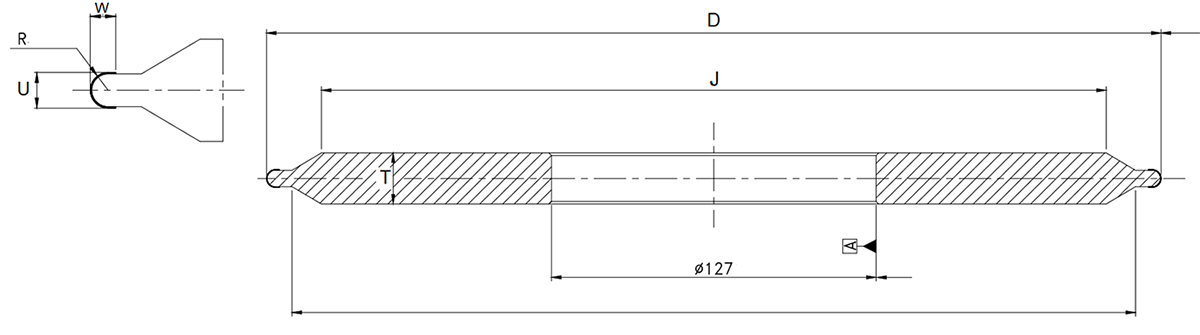

D |

H |

R |

T |

|

250 / 350 |

127 |

1 / 1.5 / 2 / 3.5 / 5 |

20 |