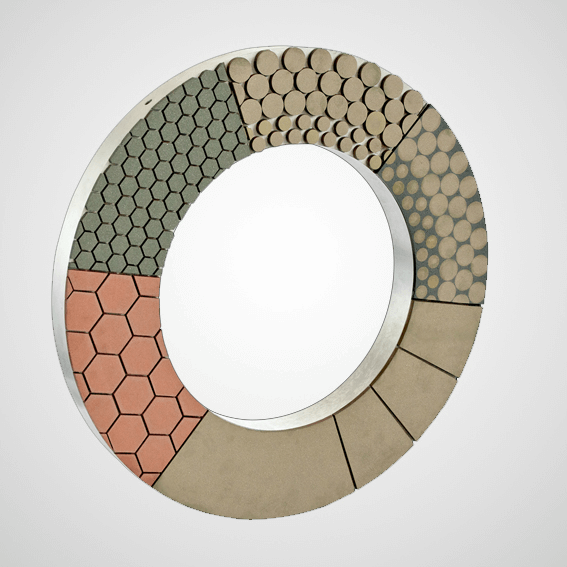

Resin bond superabrasive grinding discs

Main features:

Efficient batch double and single side grinding

High durability and long life

High parallelism and flatness of workpiece

Good surface quality

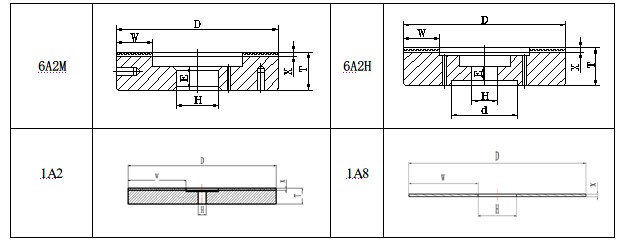

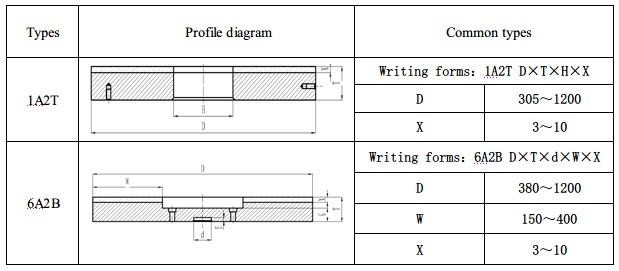

Models and profile sketches:

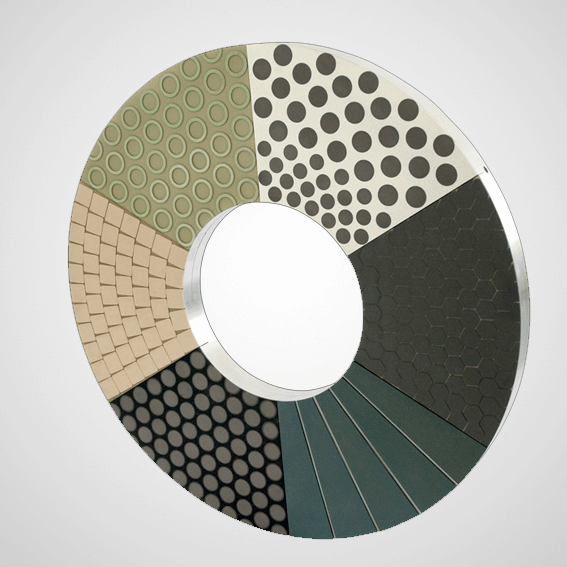

Vitrified bond superabrasive grinding discs

Main features:

1.High workpiece precision

2.High efficiency

3.Low processing cost

4.Wide applications

5.Clean working environment

Models and profile sketches:

Note: We can design and produce grinding tools of other specifications according to customers’ requirement apart from the above specs.

•Electronics –

Substrate: wafer chips for microelectronic circuits.

-Telecommunications, data processing, measuring and control engineering,

-military and aerospace industry, automotive, consumer and medical electronics

-Casing for diodes and vacuum switch chambers -Ceramic capacitors (store electrical charges) -Ceramics for high-frequency applications (disks, axles, fixtures, etc.)

-Magnetic ceramic (soft and hard ferrites /core coils, antenna rods, audio heads,

-Piezo ceramic: electro-mechanical transformers

•Electrical engineering:

-Electro-heat technology (insulation pipes/tubes, heating conductor fixtures, plate warmers, heating cartridges)

-Component parts for low-voltage engineering (circuiting and fusing)

-Carbon brushes for e-motors

•Machine construction and electronics: (“hi-tec ceramics”)

-Anti-friction and seal elements (water fittings)

-Plain, ball or roller bearings (components for heavy-duty applications)

-Jet nozzles for gaseous, liquid, solid substances

-Sensors and actors (transformers of electrical signals into fine mechanical movements) -Chemical plant construction (flasks and pump parts for the food industry and refineries)

-Thread carriers for textile machines (for thread running speed of more than 6000 m/min) -Bio-ceramics in human medicine (hip joints, dental implants, artificial limbs, etc.)

-Automotive industry (Si3N4 ceramic valves, fiber-reinforced ceramic break discs)

-Wire draw dies and molding tools -Anti-wear layers for mills

•Chemical Processing and Environmental Engineering:

-Catalytic converters for detoxification of exhaust fumes in motor vehicles (honeycomb cores) -Three-way catalytic converter with Lambda-probe -Filter and membrane technology: gas absorption, aeration and distribution of gases and liquids (hot- gas filtration)

-Nuclear engineering – radiation protection components for shielding against gamma and x-rays. -High-temperature engineering (above 1000°C): -Flame tubes and burner nozzles

-Supporting rollers for roller furnaces

-Thermal element protection tubes